When NOT to Use a Wedge-Locking Washer

Nord-Lock wedge-locking washers consistently outperform alternative locking methods when it comes to securing bolted joints. This is proven by the results of thousands of Junker tests carried out for customers all over the world by Nord-Lock engineers.

When exposed to transverse vibrations underneath the bolt head, alternative locking methods such as plain washers, helical spring washers, check lock nuts, nylon inserted nuts and double nuts all show a loss of clamp load – loosening the bolt and exposing the joint to failure unless frequently retightened.

Although other approaches like using tab washers, locking wire or adhesives are seen as safe, performance can vary significantly as they require specialist tooling, skilled operators and can often be time consuming.

So, Nord-Lock engineers would usually recommend wedge-locking washers to achieve the most secure bolted joint. However, by their own admission, there are a handful of scenarios where a wedge-locking washer might not be the most suitable method. It’s important to be aware of these in order to avoid any unwanted loosening in your bolted joints.

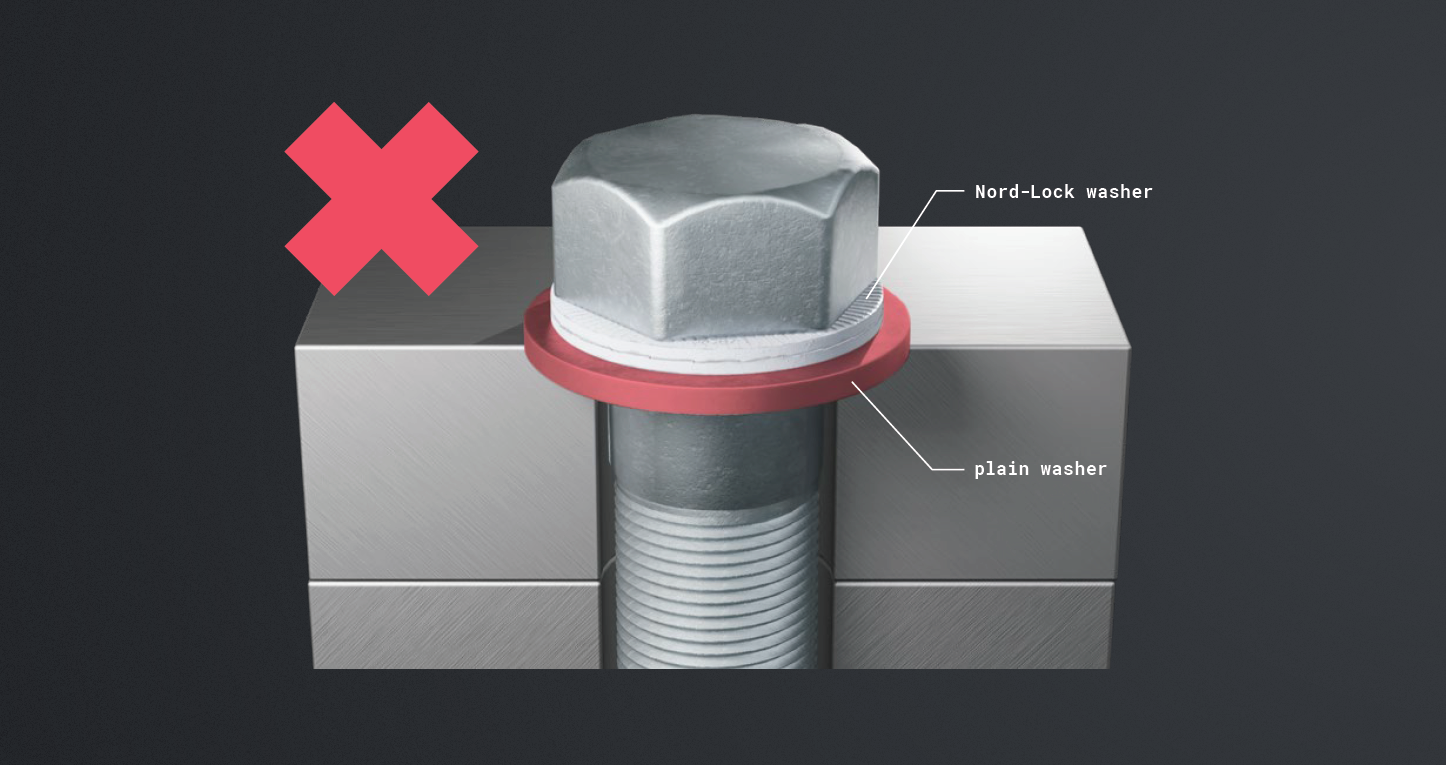

Can I use a plain washer underneath a wedge-locking washer?

No. We do not recommend using a Nord-Lock wedge-locking washer in combination with a plain washer. Serrations on the Nord-Lock washer will grip the bolt head and your plain washer, successfully locking these two together, however this plain washer will not be locked against the contact surface which means it can rotate. Effectively, this method would utilise friction (between the plain washer and contact surface) and not the wedge-locking effect that occurs between Nord-Lock washers and the clamped parts, making it virtually impossible to loosen unintentionally.

Can I use a wedge-locking washer against HARD surfaces?

Unfortunately, you cannot. To achieve the wedge-lock effect, the serrations of Nord-Lock washers must be able to make impression marks on the contact surface. For example, a porcelain surface would be too hard for the washers to make impression marks – so no installing them onto your toilet!

Can I use a wedge-locking washer against SOFT surfaces?

Not if you want to achieve a secure bolted joint. A soft material on the contact surface cannot hold the serrations, or it could be too brittle, and the bolt could start to rotate. This is the case for wood, soft plastic or any other similar materials.

How do large settlements affect Nord-Lock washers?

Clamp load in the bolted joint requires the bolt to be stretched appropriately. If the material settles, even just a few micrometres, the stretching of the bolt will decrease and will lead to a loss of preload. The loss of preload means the Nord-Lock wedge-locking effect will not work as intended, and the bolt could loosen. This is true for rubber gaskets and multi-layered joints, for example.

If in doubt – contact us!

In isolation, using a Nord-Lock washer in these scenarios above will not provide a secure bolted joint – but it may still be possible to find a solution. For example, if you’re working with a hard surface but have multiple holes for bolted joints that are close together, it may be possible to add a 1mm steel plate between the clamped parts and Nord-Lock washers. In this case, the steel is softer than the washers and it would be possible to achieve the impression marks required for the wedge-locking effect to work.

Nord-Lock Group has a world-class, global team of engineers that are always ready to deliver. Having tightened and secured billions of bolted connections in millions of applications, we use that experience to find optimal, long-term solutions to any bolting challenge and work closely with you to understand your needs, solve your problems and support your projects.

Our services focus on life cycle profitability, design, production, training and installation support. If you have an engineering challenge, we will provide you with a solution that maximizes the productivity, safety and reliability of your application.